Phoseon Technology revolutioniert die Schmalbahndruckindustrie durch die Kombination von Flexodruck, der seit mehr als einem Jahrhundert für den Druck verwendet wird, und UV-LED-Härtungstechnologie, die Phoseon 2009 erstmals in der Schmalbahnindustrie eingeführt hat.

Die Technologie von Phoseon nutzt UV-LED-Licht zum schnellen Aushärten von Druckfarben, was zu einer höheren Produktqualität führt, ohne dass lösungsmittelbasierte Druckfarben verwendet werden müssen.

"Mit UV-LED können Sie eine breitere Palette von Druckaufträgen mit höherer Qualität, schneller und konsistenter erledigen."

Jennifer Heathcote, Regional Sales Manager, Phoseon Technology

Beim Flexodruck wird eine flexible Reliefplatte - eine moderne Version des Buchdrucks - verwendet, um auf fast alle Arten von Materialien zu drucken, von Papier über Kunststoff bis hin zu Metallfolien. Im Gegensatz zu lösungsmittel- oder wasserbasierten Flexodruckfarben trocknen UV-Tinten fast sofort, wenn sie UV-Licht ausgesetzt werden, was zu einem scharfen und farbigen Bild führt. Mit einer UV-LED-Lösung ermöglicht es Phoseon den Verarbeitern, die Vorteile der UV-Härtung zu nutzen, ohne die typischen Kosten und Gefahren des Betriebs einer Bogenlampe zur Erzeugung des UV-Lichts.

"Mit UV-LED können Sie ein breiteres Spektrum an Druckaufträgen mit höherer Qualität, schneller und konsistenter erledigen", sagt Jennifer Heathcote, Regional Sales Manager bei Phoseon Technology.

Der Schmalbahndruck - ein Begriff, der sich in erster Linie auf eine Druckbreite unter 30 Zoll bezieht - wird häufig zum Bedrucken von Etiketten, Plastiktüten und flexiblen Verpackungen verwendet. Neben der höheren Qualität ermöglicht die UV-LED-Härtung für den Flexodruck eine bessere Prozesssteuerung, weniger Makulatur und die Möglichkeit, Druckmaschinen schneller laufen zu lassen als bei herkömmlichen Schmalbahndruckverfahren.

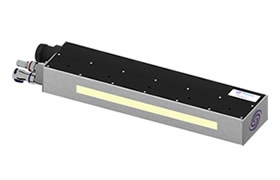

Der FirePower FP601 ist eine wassergekühlte Lösung mit fortschrittlichen Steuerungsfunktionen über eine Modbus-Schnittstelle und einer hohen Intensitätsleistung für schnellstmögliche Aushärtungsgeschwindigkeiten. Der FireJet™ FJ601 vereinfacht Nachrüstungen mit einem eigenständigen luftgekühlten Design, das die Notwendigkeit von Luftabsaugsystemen oder Wasserkühlungen überflüssig macht.

Neben dem Schmalbahndruck wird die UV-LED-Technologie von Phoseon Technology auch in einer Vielzahl anderer Anwendungen eingesetzt, z. B. im Breitbahn- und Dekordruck, bei der Herstellung von Holz und der Aushärtung von Holz- und Filamentbeschichtungen.

Tags: UV-LED-Flexo | LEDinside Magazin | UV-LED-Härtung für SchmalbahnanwendungenKategorien: Druck, Flexo