Nazdar Ink Technologies has partnered with Focus Label Machinery to help drive the growth of UV LED technology within the label converter market in the UK and EMEA. The two businesses are now working closely together to demonstrate the efficiency of UV LED curing technology at Focus Label Machinery’s Bingham, Nottinghamshire-based offices.

With a mutual interest in the technology, both companies share an objective to showcase how – alongside traditional products – UV LED curing technology is a commercially-viable option for the label and packaging producer.

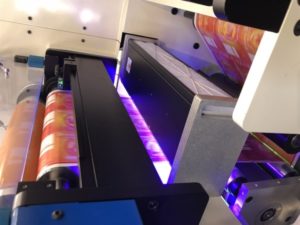

James Thomas, Business Development and Marketing Manager at Focus Label Machinery, explains: “We demonstrated Phoseon UV LED technology at our Open House event earlier this year. Following great feedback from visitors, we decided to fully fit our 6-colour e-flex press with Phoseon lamps and after completing some ink trials are now running Nazdar inks to demonstrate the benefits of UV LED technology to the label and packaging market.”

Jim Whitehead, Nazdar’s Sales Manager for EMEA, with responsibility for the flexo technology sector, adds: “Many label and packaging converters don’t fully appreciate the breadth of UV LED curing ink products that Nazdar has – and the benefits they offer. We are thrilled to be able to support Focus Label Machinery with their push to demonstrate the technology and provide the newest UV LED curing equipment on the market.”

“We demonstrated Phoseon UV LED technology at our Open House event earlier this year. Following great feedback from visitors, we decided to fully fit our 6-colour e-flex press with Phoseon lamps.”

James Thomas, Business Development and Marketing Manager, Focus Label Machinery

Nazdar flexo inks offer no compromise to the label converter compared to conventional UV systems with a broad range of product available including metallics, peel and reseal coatings and Nestle compliant inks, curing at high speed and offering equal colour strength to conventional curing ink systems. By combining these inks with a UV LED system, label converters can save energy – which, in turn, reduces costs.

UV LED lamps also use far less energy than conventional mercury lamps and there is no ozone production, so less extraction is required. Lower heat output from lamps means it is easier to manage temperature-sensitive substrates.

Other benefits include a longer lamp life and therefore less maintenance downtime compared to mercury lamps, and less heat-up time as UV LED lamps are ready to work in minutes. Peak output is also better maintained with UV LED technology, improving print consistency, and users can take advantage of high production speeds up to 300m/min.

James Thomas concludes: “We are delighted to be working alongside a company such as Nazdar who have a wide experience in UV LED curing technology and depth of product range. The partnership will enable us to demonstrate the efficiency of UV LED curing technology and the full capability that the technology offers.”

As part of its commitment to deliver high performance ink solutions to end-users, Nazdar has developed a full range of UV LED technology flexo ink solutions – including thermal varnishes, foiling and laminating adhesives, peel and reseal packages and more. For more information on Nazdar and its comprehensive range of narrow web ink solutions, please visit www.nazdar.com/narrow-web-inks.

With a full range of machinery for the label market, Focus Label Machinery has built up a strong product portfolio based specifically around UV LED curing technology. For more information on Focus Label Machinery, please visit www.focuslabel.com.

Tags: Nazdar Ink Technologies | Focus Label Machinery | UV LED TechnologyCategories: