Phoseon is donating FireJet FJ605 light sources with Flex Tower and mounting brackets.

Phoseon Technology is donating LED curing systems to Clemson University’s Sonoco Institute to help support the future generation of professionals in flexographic printing applications to have hands-on experience with UV LED curing, learning all of the benefits and capabilities enabled with UV LED.

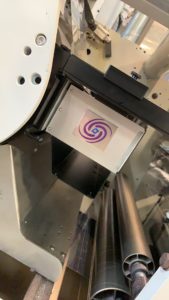

In partnership with OMET Americas, Phoseon is donating FireJet FJ605 light sources with Flex Tower and mounting brackets, which are installed in OMET’s Varyflex narrow-web press. This press is housed in the Institute’s Advanced Print Lab for hands-on training and will be showcased at the upcoming “Open House, The Future of Flexo: New Year, New Technology” presented by OMET.

“With this collaboration, we are empowering and supporting the future of flexographic and other printing applications designers.”

Keate Despain, VP of marketing, Phoseon

The Open House will take place at the Sonoco Institute Feb. 6-7 in Clemson, SC.

The light source is equipped with Phoseon’s patented TargetCure and WhisperCure technologies providing users with stable, consistent and precise UV output, along with a quiet operating level while maintaining a high UV output.

The Flex Tower provides a configurable power and control system for flexographic and narrow web applications, with easy installation for upgrading presses to the newest technology.

“With this collaboration, we are empowering and supporting the future of flexographic and other printing applications designers,” said Keate Despain, VP of marketing for Phoseon. “Phoseon is proud to be working with students and customers in their development of innovative and game-changing capabilities that is not only good for a company’s bottom line but is also good for the environment. This new Center of Excellence for UV LED curing at the Sonoco Institute enables Phoseon and partners to demonstrate UV LED curing capabilities to those interested in converting from traditional mercury lamps.”

Tags: FireLine FL440 | Ink World MagazineCategories: Printing, Flexo