What is Ultraviolet Wavelength?

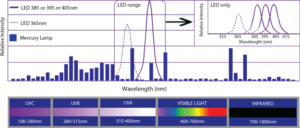

The sun is a source of the full spectrum of ultraviolet radiation, which is commonly subdivided into UVA, UV-B, and UV-C. Wavelength, a fundamental descriptor of electromagnetic energy, is the distance between corresponding points of a propagated wave. Typical UV light source emission wavelengths range from ultraviolet (UV-C: 100 to 280nm; UV-B: 280 to 315nm; UV-A: 315 to 400nm) to visible light (400 to 700nm) and infrared (700 to 3000nm).

UV wavelengths typically are measured in nanometers (nm). Nanometer, a unit of length, is equal to one billionth of a meter. UV light-emitting diodes (LEDs) have a narrow spectral output centered on a specific wavelength, +/- 15nm, with typical commercial UV LED lamps emitting at 365nm, 385nm, 395nm or 405nm wavelengths. The irradiance (W/cm2 ) produced by UV LED light sources has increased consistently year over year because of advancements in both diode and lamp technology, and now is available at effective outputs higher than those offered by traditional UV curing lamp technologies. UV LED lamp systems have enough power to conquer a wide range of applications and today are being used commercially to cure inks, coatings and adhesives.

“UV LED curing units have become more efficient in delivering UV energy to the media, thus driving not only environmentally clean, energy-efficient and compact-size units but also enabling increased throughput and process flexibility.”

Mike Higgins, east regional sales manager, Phoseon

UV energy emitted from UV LED lamps and UV energy emitted by conventional mercury arc lamps or microwave lamps is all in the form of photons of specific wavelengths. That is, for purposes of UV photopolymerization, photons are photons, with the only differences being in quantity and wavelength. The distribution of wavelengths emitted by UV LED lamps is much narrower than the distribution of wavelengths emitted by conventional UV sources, and as a result, formulations and radiometers used with UV LED lamp systems must be matched to the emission bands of the UV LED lamp used in that curing system to achieve optimal performance.

UV LED-based curing is now an accepted, user-friendly tool in printing, coatings and adhesive markets, and UV LED system characteristics are enabling a number of applications that were impractical or limited by physical constraints of conventional UV sources. These industry users and UV LED suppliers continue to challenge formulators and chemical raw material suppliers to develop and supply UV LED wavelength-optimized materials and formulations. At the same time, UV LED curing units have become more efficient in delivering UV energy to the media, thus driving not only environmentally clean, energy-efficient and compact-size units but also enabling increased throughput and process flexibility.

Tags: UV+EB Technology Magazine | UV LED Wavelength | UV LED TechnologyCategories: Adhesives | Chemistry | Corporate | Inks | Printing, Digital | Printing, Flexo | Printing, Screen