Applications

UV LED curing solutions are being rapidly adopted for curing adhesives in factory assembly lines throughout the world. Low operating costs, long lifetime, and low maintenance are just a few of the reasons. Additionally, small electronic components maybe sensitive to heat and UV LED overcomes those issues by being a ‘cool’ light source.

- Electronics

- Medical

- Automotive

- Manufacturing/Assembly

- Area Curing

- Spot Curing

Electronics

UV LED technology is a perfect match for adhesive curing components such as speakers, camera modules, display screens, and printed circuit boards. The unique combination of high-energy UV LED sources with the appropriate adhesive provides increased productivity, while also providing the ability to cure heat sensitive materials.

Medical

UV adhesive curing for medical applications such as: syringes, catheters, IV delivery systems, endoscopes, hearing aids. UV LED curing technology minimizes the heat load to the work surface allowing for capability with heat-sensitive applications. The long lifetime, instant on/off control and consistent UV output can improve process variation and control.

Manufacturing/Assembly

Additional manufacturing processes such as solar panels, glass, metals, elastomers, composites and many plastics lend themselves to using UV LED curing. UV LED light sources are utilized in a wide range of industrial applications due to their long-life and high reliability.

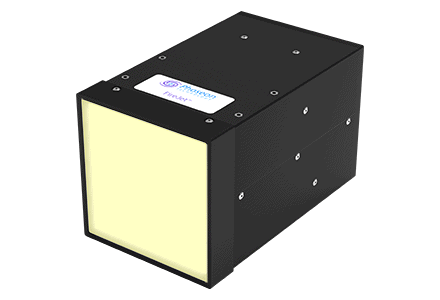

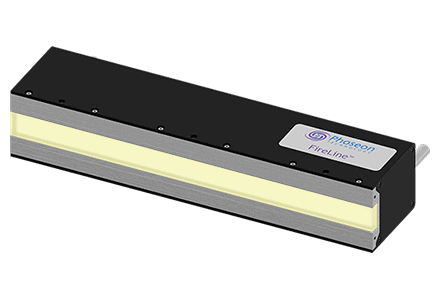

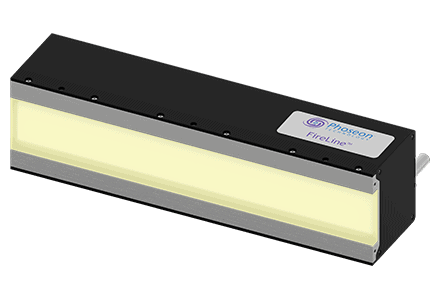

Area Curing

Area curing solutions target adhesives cure applications, mainly in electronics manufacturing production lines and lab material/substrate curing. Starting from a base curing area of 100 x 100 mm, these modular products can scale in three directions to provide contiguous, uniform UV output.

Power Spot Curing

Use a UV LED lamp that is larger than the typical spot curing pen and offers significantly more power.