응용

전 세계 공장 조립 라인에서 접착제를 경화하기 위해 UV LED 경화 솔루션이 빠르게 채택되고 있습니다. 낮은 운영 비용, 긴 수명, 낮은 유지보수는 그 이유 중 일부에 불과합니다. 또한 소형 전자 부품은 열에 민감할 수 있는데 UV LED는 '차가운' 광원이기 때문에 이러한 문제를 극복합니다.

- 전자제품

- 의료

- 자동차

- 제조/조립

- 부위 경화

- 스팟 경화

전자제품

UV LED 기술은 스피커, 카메라 모듈, 디스플레이 스크린, 인쇄 회로 기판과 같은 접착제 경화 부품에 완벽하게 어울립니다. 고에너지 UV LED 광원과 적절한 접착제의 독특한 조합은 생산성을 높이는 동시에 열에 민감한 소재를 경화할 수 있는 기능을 제공합니다.

의료

주사기, 카테터, IV 전달 시스템, 내시경, 보청기 등 의료용 UV 접착제 경화. UV LED 경화 기술은 작업 표면의 열 부하를 최소화하여 열에 민감한 애플리케이션에 사용할 수 있습니다. 긴 수명, 즉각적인 온/오프 제어, 일관된 UV 출력으로 공정 변화와 제어를 개선할 수 있습니다.

제조/조립

태양 전지판, 유리, 금속, 엘라스토머, 복합재 및 많은 플라스틱과 같은 추가 제조 공정은 UV LED 경화를 사용하기에 적합합니다. UV LED 광원은 수명이 길고 신뢰성이 높기 때문에 다양한 산업 분야에서 활용되고 있습니다.

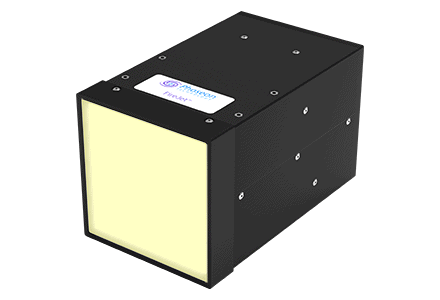

부위 경화

영역 경화 솔루션은 주로 전자 제품 제조 생산 라인과 실험실 재료/기판 경화에서 접착제 경화 응용 분야를 대상으로 합니다. 기본 경화 영역 100 x 100mm에서 시작하는 이 모듈식 제품은 세 방향으로 확장하여 연속적이고 균일한 UV 출력을 제공할 수 있습니다.

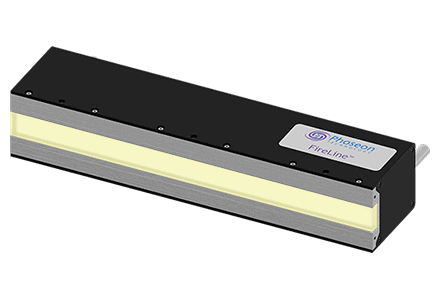

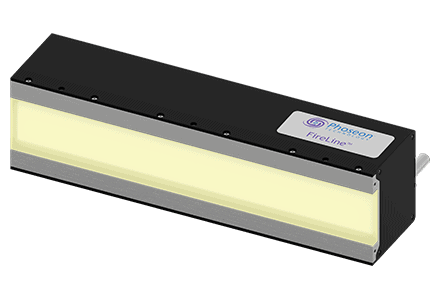

파워 스팟 경화

일반적인 스팟 경화 펜보다 크고 훨씬 더 강력한 출력을 제공하는 UV LED 램프를 사용합니다.