Phoseon技术通过将一个多世纪以来一直用于印刷的柔版印刷与UV-LED固化技术相结合,正在对窄幅印刷行业进行革新,Phoseon于2009年首次将该技术引入窄幅印刷行业。

Phoseon的技术使用UV LED光来快速定型,或 "固化 "用于印刷的油墨,从而在不使用溶剂型油墨的情况下获得更高质量的产品。

"UV LED使你能够以更高的质量、更快、更稳定地完成更广泛的印刷工作"。

Jennifer Heathcote, 区域销售经理, Phoseon Technology

柔版印刷利用柔性凸版--一种现代版的凸版印刷--在几乎任何类型的材料上印刷,从纸张到塑料到金属薄膜。与溶剂或水基柔版印刷油墨不同的是,紫外线油墨在暴露于紫外线时几乎立即干燥,从而产生鲜明而多彩的图像。通过UV-LED解决方案,Phoseon使印刷商能够享受到UV固化的好处,而没有操作弧光灯产生UV光的典型成本和危险。

"Phoseon Technology公司的区域销售经理Jennifer Heathcote说:"UV LED使你能够以更高的质量、更快、更稳定地完成更广泛的印刷工作。

窄幅印刷--一个主要与低于30英寸的印刷宽度有关的术语--经常被用于印刷标签、塑料袋和软包装。除了更高的质量外,用于柔版印刷的UV LED固化可以实现更好的工艺控制,减少浪费,并且能够比传统的窄幅印刷方法更快地运行印刷机。

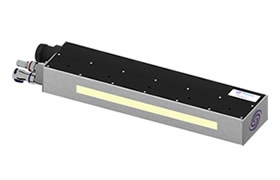

FirePower FP601是一款水冷式解决方案,具有先进的控制功能,使用Modbus接口和高强度输出,可实现最快的固化速度。FireJet™ FJ601通过独立的风冷设计简化了改装,不需要空气抽吸系统或水冷系统。

除了窄幅印刷,Phoseon Technology的UV LED技术还被广泛用于其他领域,如宽幅印刷和装饰性印刷,制造木材,以及固化木材和长丝涂料。

标签 紫外线LED柔印 | LEDinside杂志 | 窄网应用中的UV LED固化技术岚,巗峃。 印刷,柔印