应用领域

Phoseon的 UV LED纤维固化系统 在固化光纤和线材应用方面具有诸多优势,包括光纤、电线和结构线以及智能织物用线。Phoseon 提供完整的 UV LED 系统,与传统的紫外光或弧光固化相比,该系统具有许多优势和优点,例如在光纤和线材的全直径范围内实现快速、更一致的固化效果,降低运营成本,提高产量,节能高达 70%。

UV LED 固化技术使用经过微调的光源和专有的光学元件,可以更好地控制过程,从而获得更优质、更稳定的整体产品。从日常家电中使用的铜线绝缘到舒适的服装材料中使用的涂层线,对涂层纤维和电线的需求量非常大,UV LED技术可以使固化过程更快、更有效地完成,并减少浪费。

观看纤维治疗演示

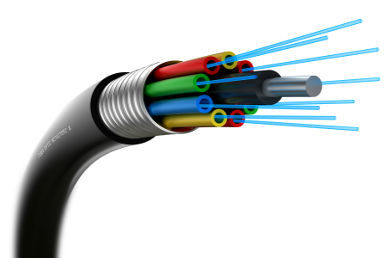

光纤

Phoseon Technology 的 纤维固化系统 该系统由一个高强度紫外线 LED 光源(用于固化保护玻璃纤维的涂层)和一个光纤反射器装置(FRU)组成,用于将紫外线能量引导到光纤的圆周上。紫外线 LED 光源和 FRU 都封装在 IP52 防护等级的外壳中,可防止液体溢出。LED 技术大大降低了能耗,并显著降低了工件表面温度。对于需要过程监控的应用,FRU 包括一个用于辐照度监控系统的安装功能。

电气和结构线缆

UV LED固化解决方案正迅速被用于金属线的固化涂层。这些涂层包括用于磁力线的电气绝缘材料和结构线的腐蚀保护。低运营成本、长寿命和低维护成本只是UV LED被选择而不是其他固化方法的几个原因。用于电线和结构线的UV LED固化使用微调的光源,可以实现更好的过程控制,从而获得更优质、更一致的整体产品。这种过程控制可以提高产量,减少制造商的废品。此外,改用UV固化涂层材料还可以消除溶剂型涂料中含有的VOCs。

智能织物

智能面料,又称智能纺织品或电子纺织品,是指嵌入特殊材料的面料,可以实现服装的新功能。智能织物的开发中嵌入了数字元件和电子元件,以及对环境或穿戴者身体做出反应的材料。这些面料针对各种应用,包括医疗、健康和运动监测,如心率、温度和呼吸频率。它们还可用于军事和工业应用,在这些应用中,位置和环境变量非常重要。

许多为智能织物应用而开发的材料都可以用UV固化。而且由于UV LED固化比传统的电弧灯或微波灯产生的热量更少,因此制造商可以在细线上涂上可能被热损坏的特殊化学品。