Overview

High intensity UV LED surface disinfection for manufacturing deserves serious consideration where disinfection and decontamination is required. High irradiance, combined with appropriate wavelengths, targets specific bonds in DNA, RNA and proteins within microorganisms and biomolecules. This allows shorter inactivation times while improving overall efficacy of the disinfection. The high absolute irradiance of these new solutions enable high-throughput processes for manufacturing facilities.

Phoseon developed the first 275nm UV LED disinfection system that surpasses 5 W/cm², significantly higher than other technologies in the market. This milestone development enables us to produce a level of irradiance that provides manufacturers the capability to think and act beyond traditional methodologies. For the past 30 years, low irradiance has limited the efficacy of UV-C solutions. Phoseon builds high-performance; long-lasting UV LED products and provides customers improved disinfection capabilities. Contact us to learn more about UV LED surface disinfection for manufacturing.

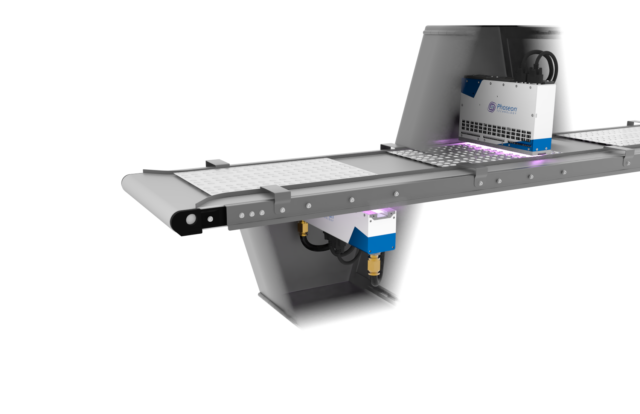

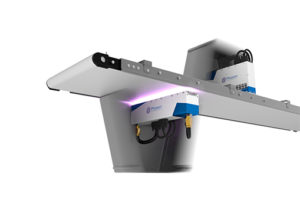

Conveyor Disinfection

UV LED technology is ideally suited for disinfection of conveyor belts to inactivate pathogens after the products have passed through the conveyor.

Learn More

Food and Beverage Processing

UV LED technology offers significant process improvements and new capabilities in many food and beverage processing applications. UV LED technology inactivates pathogens during food and beverage processing.

Learn More

Packaging Materials

Disinfection of surfaces is essential for maintaining the cleanliness of medical, pharmaceutical, food, beverage, and other packaging materials.

Learn More