Soluzioni retrofit per LED UV Nexus ONE™

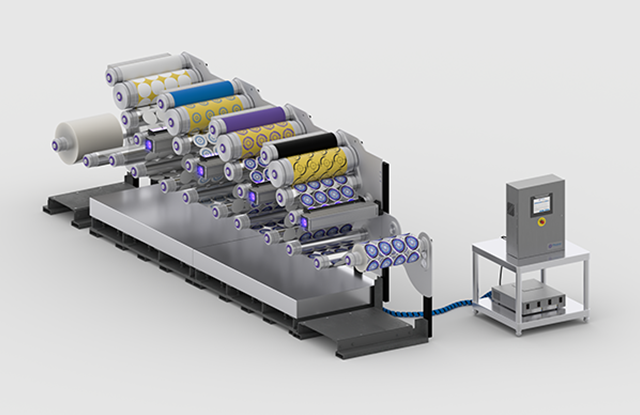

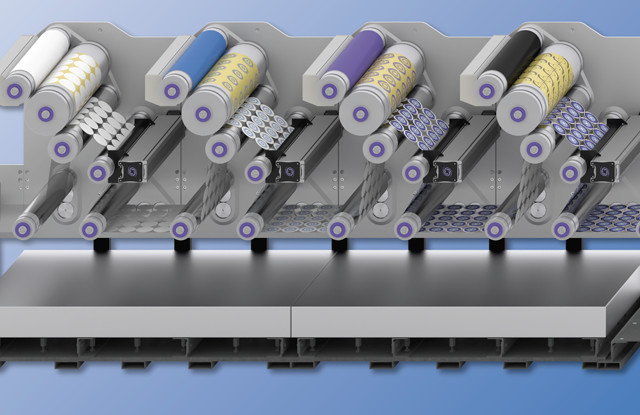

I sistemi di polimerizzazione UV LED Nexus ONE™ sono ideali per le applicazioni di stampa flessografica e offrono la soluzione più performante del settore. Con un numero di diodi LED 2,5 volte superiore a quello dei prodotti della concorrenza e tecniche di gestione termica brevettate, i prodotti Nexus ONE offrono la massima potenza UV totale per ottenere una maggiore velocità di stampa, un maggiore tempo di attività della macchina da stampa e una durata doppia del prodotto. Nexus ONE è il primo sistema di polimerizzazione UV a LED disponibile con una garanzia di cinque anni per l'intero sistema, offrendo ai clienti una protezione dell'investimento.

Le soluzioni Nexus ONE completamente integrate comprendono le sorgenti luminose e il sistema di alimentazione e controllo Nexus Tower. La Torre Nexus offre un sistema di alimentazione e controllo configurabile, fornendo una soluzione completa per le nuove installazioni e gli aggiornamenti retrofit. I kit di installazione retrofit sono facili da installare e possono essere completati dai nostri tecnici esperti.

Aggiornate la vostra macchina da stampa oggi stesso

Aumentare la redditività

Poiché i problemi di polimerizzazione UV sulla macchina da stampa sono tipicamente il risultato di lampade al mercurio difettose, della formulazione o del processo di conversione, l'uso della tecnologia UV LED elimina il sistema di polimerizzazione UV come fonte del problema. Ciò consente di risparmiare tempo nella risoluzione dei problemi e, in ultima analisi, ha un impatto positivo sui profitti. A differenza delle lampade di polimerizzazione UV a mercurio, i LED UV non emettono ozono, eliminando la necessità di grandi sistemi di soffianti o di condotti per l'aria di scarico e consentendo ai trasformatori di ottimizzare lo spazio a disposizione.

- Rese più elevate grazie a una polimerizzazione affidabile

- Aumento del tempo di funzionamento della pressa

- Un throughput più veloce

- Risparmio energetico da 50% a 80%

- Nessun costo di smaltimento per le lampadine al mercurio

- Riduzione dei costi operativi

Migliorare la capacità

Se equipaggiate la vostra macchina da stampa con i sistemi di polimerizzazione UV LED Nexus ONE, spingerete le vostre prestazioni a livelli mai raggiunti prima. L'intensa emissione UV, abbinata agli inchiostri flessografici UV LED, consente di raggiungere velocità di stampa record. La bassa emissione di calore consente nuove funzionalità, quali materiali sensibili al calore, pellicole non supportate e substrati più sottili, richiedendo al contempo meno manutenzione ed energia.

- Bianchi opachi di qualità superiore e neri densi

- In profondità attraverso la polimerizzazione

- Substrati sensibili al calore

- Gamma UV metallica

- Colori fluorescenti senza sbiadire

- Basso processo di migrazione

Aggiornare la stampa

Sei interessato a saperne di più sulle nostre soluzioni di polimerizzazione UV LED per la stampa flessografica? Contattateci oggi stesso con la vostra applicazione.