Overview

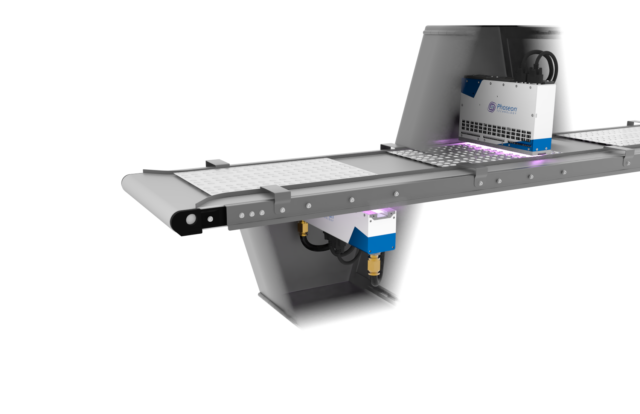

Disinfection of surfaces is essential for maintaining the cleanliness of pharmaceutical, medical, food, beverage, cosmetic or other manufacturing operations. These packaging materials can be disinfected using a variety of methods such as chemical or heat processes that can be very time consuming and expensive. Phoseon offers high intensity UV LED disinfection for packaging materials, an ideal alternative to traditional methods.

High intensity UV LED technology offers unmatched levels of deep UV irradiance, which enable significant process improvements, including faster analysis and operations, and increased capabilities for decontamination and disinfection applications that require low wavelengths. UV LED technology enables complete inactivation of contaminants in minutes compared to traditional methods.

Manufacturing processes have a new tool to improve throughput, yield, and quality. Phoseon’s Semiconductor Light Matrix (SLM)™ technology provides customers with increased capabilities for pharmaceutical, food, cosmetic and other disinfection and decontamination applications. By leading with science, Phoseon optimizes the disinfection process and brings this new capability to market. Contact us to learn more about disinfection for packaging materials.

Pharmaceutical Packaging

UV LED disinfection of surfaces is essential for maintaining the cleanliness of pharmaceutical packaging.

Learn More

Food Packaging

UV LED technology offers significant process improvements and new capabilities in many food processing applications.

Beverage Processing

UV LED technology offers significant process improvements and new capabilities in many beverage processing applications.

Learn More