Overview

Countless manufacturing processes make use of the benefits of UV LED curing. Applications range from high-speed curing of coatings to curing colorings of the finished products.

Phoseon’s UV LED curing products are utilized in a wide range of industrial coating applications due to their long-life and high-reliability. The majority of Phoseon’s customers have unique requirements for a curing lamp to either fit an existing process or develop a new one. By taking advantage of UV LED curing, industrial companies are able to lower their overall energy usage, regain floor space, and improve worker safety.

Air-cooled products such as the FireJet family provide a simple, economical method of achieving high peak irradiance. For higher energy requirements, Phoseon offers water-cooled systems such as FirePower. These products are not impacted by ambient air temperature and are ideally suited for tight process control.

Coatings Applications Overview

Manufacturing, Design & Repair

Industrial processes require products that can work in tough, sometimes harsh manufacturing, design and repair environments. Automated processes work with UV LED curing lamps due to being a solid-state, semiconductor based device that allows for instant on-off or variable irradiance control of the UV energy. UV LED curing enables customers to speed up their processes, reduce costs, and increase quality. UV LED curing includes but is not limited to manufacturing solar panels, wood/plastic coatings, thin films, bottle processing, rapid design prototyping via 3D printing and wind turbine repair.

Functional & Decorative

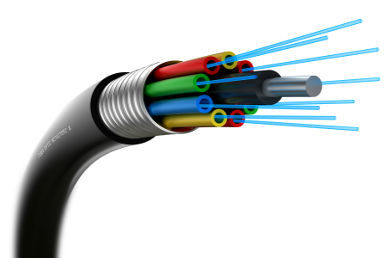

Coatings used in industrial processes have stringent requirements. These products are typically manufactured in large volume with a need for process consistency. UV LED curing lamps are an ideal fit for these requirements as they can be built in various configurations (lengths, widths, irradiance intensity) with more control over applied dose to increase manufacturing throughput and product performance. Functional coatings are used for wood roller coating, fiber optics and several automotive components. Decorative examples include: digital printing of wood, coloring of wire and fiber, and automotive trim.

Assembly

Phoseon products work with with a large number of assembly applications and industrial processes. We offer various product solutions all designed to meet customers’ manufacturing requirements from small-to-large scale. Phoseon Technology’s products are UV LED-based which minimizes the heat load to the work surface allowing for capability with heat-sensitive applications. The long lifetime, instant on/off control and consistent UV output can improve process variation and control making them versatile for various wide range of applications. Phoseon’s UV LED curing products are ideal for UV curing for small area cure with high volume and low cost applications.