The Inventor of UV LED Curing

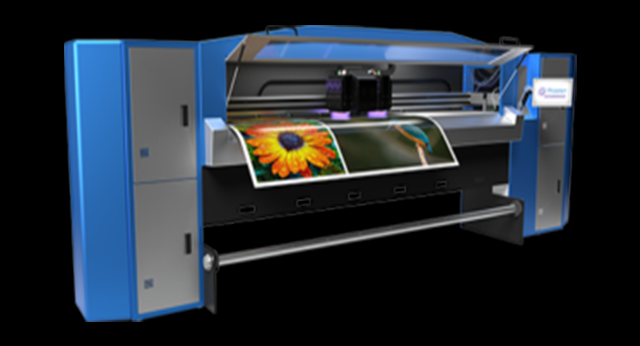

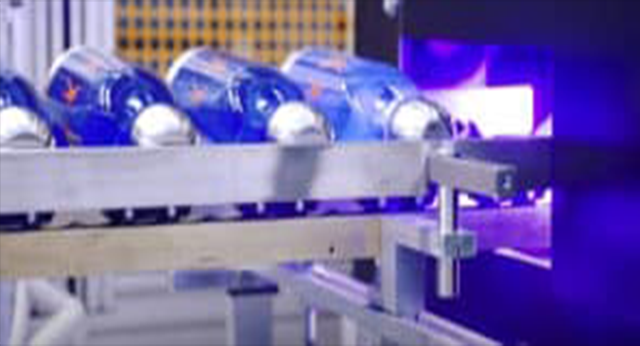

As the industry pioneer, Phoseon provides the broadest portfolio of LED-based solutions for drying inks, coatings, adhesives and other UV sensitive materials through polymerization. With over 300 patents and trademarks protecting more than 150,000 units shipped, Phoseon has earned a worldwide reputation for innovation, quality and reliability. Phoseon provides LED curing solutions to a wide-range of applications and market segments including: labels and packaging, container decoration, digital printing, wire and fiber coatings, electronics, automotive assembly, medical devices, wood furniture, and many more.

LED Curing ApplicationsUV LED Curing Solutions

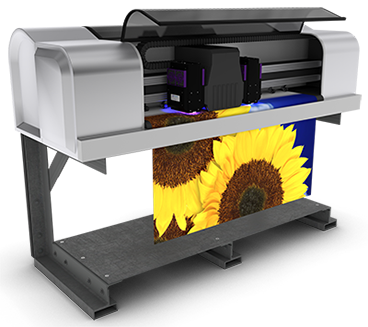

Nexus ONE™ Products for Flexographic Printing

Phoseon Technology introduces Nexus ONE™ sustainable UV LED curing products for flexographic printing applications. Nexus ONE premium UV LED curing lamps deliver maximum power and dose of UV energy for the flexographic markets where high performance is a key requirement. By enabling quality applications at faster press speeds, the Nexus ONE is truly the all-in-one UV LED curing product for flexographic printing. Invest in your future now!

Learn More

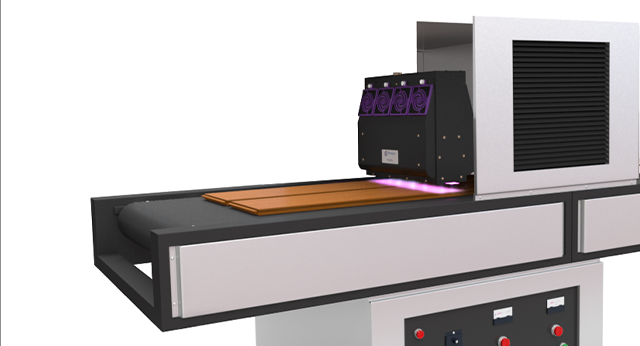

Eco-Friendly LED Curing Technology

At Phoseon, we are fully committed to the wellbeing of the environment. We continuously work to reduce the environmental impact of the products that we manufacture. Phoseon LED curing solutions offer consistent and reliable power output, eliminates greenhouse gas, and removes mercury in an entire category of industrial processes. Allow us to contribute to your corporate sustainability objectives TODAY!

Learn More

Contact Us

Are you interested in learning more about our UV LED curing solutions? Please contact us today with your application.

Contact Us