Flexographic Application Offerings

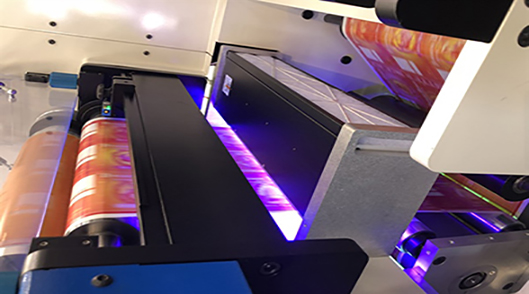

UV LED technology opens the door to new flexographic application opportunities with the ability to print on heat-sensitive and thinner substrates, offering increased profitability for printers and converters.

Flexo Products

Phoseon products offer increased capabilities for flexographic printing with UV LED curing. The intense UV output paired with UV LED flexo inks achieved record press running speeds. The low heat output enables new capabilities such as heat-sensitive materials, unsupported films, and thinner substrates while requiring less maintenance and energy.

Due to the long wavelength range of UV LED, it has the ability to cure previously difficult inks with reliably higher quality at faster speeds. UV LED inks are available with colors matched to traditional inks for a smooth transition. Check with your ink supplier for details.

Flexo Products

Increased Capability

- Higher quality opaque whites & dense blacks

- Multiple thick layers cured all the way through with good inter-layer adhesion

- Low/high Coefficient of Friction (COF) whites for shrink application

- UV Metallic range

- Fluorescent colors without fading

- Wide range of coatings

- UV adhesives, both for lamination and Pressure Sensitive Adhesives (PSA), as well as for cold foil

- Low migration/food packaging

Substrates and Applications

With no IR heat, converters using UV LED technology can add new capability to a press, previously unable to run thin and heat sensitive films, eliminating the need for chill rolls.

Proven Substrates:

- Heat sensitive films (shrink/unsupported)

- 0.75 to 2 mil BOPP

- 64% PVC shrink film

- Semi-Gloss

- 1.4 mil Polypropylene

- 2 mil Polystyrene

- Direct thermal paper

- Metalized pouch material

- Pressure sensitive labels – paper and film

- Lamination