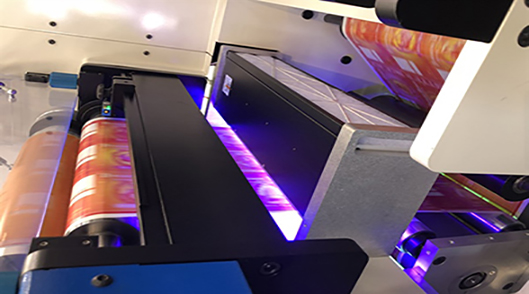

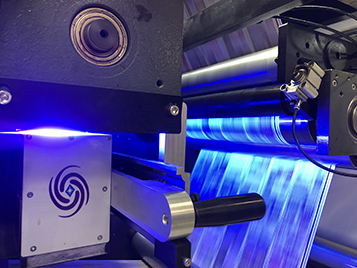

LED Curing Solutions for Flexo

Phoseon provides UV LED curing solutions for both new and retrofit narrow web presses. Phoseon’s 100% focus on UV LED solutions offers higher yields and decreased operating costs for increased profitability. Phoseon’s patented LED technologies deliver rugged, high-performance solutions for demanding narrow-web applications. Additionally, Phoseon’s UV LED technology enables ink manufacturers to provide true low-migration solutions for food packaging.

Customer Applications and Case Studies

Below is a collection of cases studies and other supporting material that will help the integrator and/or end user better understand how to maximize the benefits of their Phoseon product as well as a small sample of applications that currently use UV LED curing.

Market Segments

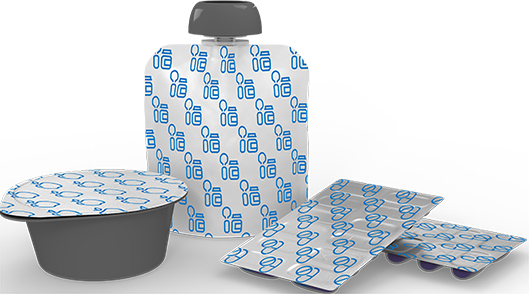

Phoseon offers UV LED curing solutions for a broad variety of packaging for flexographic and narrow web, enabling high-speed printing on a wide range of materials such as labels, packaging and decorative printing. The intense output, low heat, and reduced energy usage of Phoseon UV LED systems has enabled printers and converters to decrease material and operating costs while providing customers with superior product.

Market Segments

Upgrade Your Press

Are you interested in learning more about our UV LED curing solutions for flexo printing? Please contact us today with your application.

Request More Information