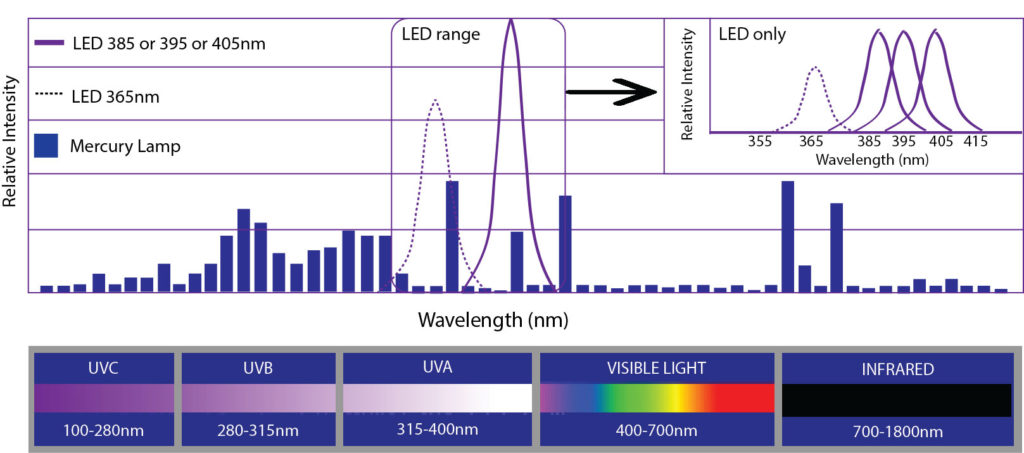

UV LED vs. Mercury Spectral Distribution

The Sun is a source of the full spectrum of ultraviolet radiation, which is commonly subdivided into UV-A, UV-B, and UV-C. The typical light source spectrum wavelength ranges from Ultraviolet Light (UV-C: 200 to 280nm; UV-B: 280 to 315nm; UV-A: 315 to 400nm) to Visible Light (400 to 760nm) and Infrared Light (760 to 3000nm). LED UV lights have a narrow spectral output centered around a specific wavelength, ±10nm. Most Phoseon products use 365nm, 385nm, 395nm or 405nm wavelengths. This near-monochromatic distribution (see chart) requires new chemical formulations to ensure proper curing of inks, coatings, and adhesives.

The majority of standard UV curing happens in a narrow emission range with the remainder of the spectral output generating unneeded and potentially harmful UV-C and infrared emissions. UV LED lights provide this narrow emission range.

UV LED curing light sources efficiently convert 20-40% of the input electrical power into usable UV light with no harmful UV-C or infrared exposure. That efficiency translates into approximately 80% power and heat savings over mercury based lamps.

Peak Irradiance & Energy Density

There are two key parameters of an LED lamp that should be understood for the purposes of optimizing cure and establishing a process window. Identifying this process window will result in the most durable and desirable finish, as well as acceptable adhesion and surface cure: peak irradiance and energy density.

Peak irradiance, also called intensity, is the radiant power arriving at a surface per-unit area. With UV curing, the surface is the cure surface of the substrate or part, and a square centimeter is the unit area. Irradiance is expressed in units of watts or milliwatts per square centimeter (W/cm² or mW/cm²). Peak irradiance is instrumental in penetration and aiding surface cure. Peak irradiance is affected by the output of the engineered light source, the use of reflectors or optics to concentrate or contain the rays in a tighter surface impact area, and the distance of the source from the cure surface. The irradiance for UV LEDs at the cure surface decreases quickly as the distance between the source and the cure surface increases.

Energy density, also called dose or radiant energy density, is the energy arriving at a surface per-unit-area during a defined period of time (dwell or exposure). A square centimeter is again the unit area and radiant energy density is expressed in units of joules or millijoules per square centimeter (J/cm² or mJ/cm² ). Energy density is the integral of irradiance over time. A sufficient amount of energy density is necessary for full cure.