Since 2002, Phoseon pioneered UV LED curing technology for industrial curing applications worldwide. Phoseon’s patented technology provides maximum UV energy, superior performance, and long-term reliability. UV LED improves workplace safety through the elimination of harmful substances such as ozone and mercury. These light sources perform faster, safer, cleaner, and provide a longer-lasting environmentally sustainable solution for customers. Phoseon has completed a large number of successful UV curing systems in printing, coatings and adhesive markets. Utilizing its patented technology and expertise in optics and thermal management, we provide customized solutions for customer’s tough curing challenges.

UV LED improves on the conventional processes by enabling the technology to be used with thinner, heat- sensitive substrates and constructions as well as sensitive electronics and assemblies. It simultaneously reduces byproducts such as ozone and improving workplace safety through the elimination of UV-B and UV-C wavelengths.

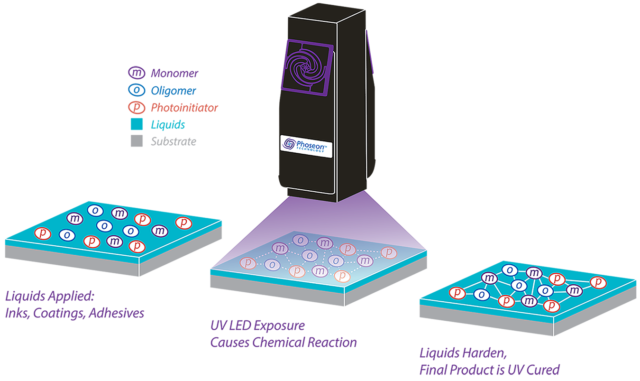

UV LED Technology

Environmentally Sustainable

Eco-Friendly LED Curing Technology

At Phoseon, we are fully committed to the wellbeing of the environment. We continuously work to reduce the environmental impact of the products that we manufacture. Phoseon LED curing solutions offer consistent and reliable power output, eliminates greenhouse gas, and removes mercury in an entire category of industrial processes. Allow us to contribute to your corporate sustainability objectives TODAY!

Prevent Toxic Mercury Bulb Waste