PHOSEON CONTINUES TO EXPAND AND IMPROVE IN RESPONSE TO THE MARKET.

Phoseon Technology has 270 patents worldwide and has delivered more than 100,000 units to its diverse customer base. Additionally, its products are designed to surpass 70,000 hours of lifetime under ideal conditions. But the company is not resting on these laurels. Phoseon is the innovative leader in UV LED solutions for life sciences and industrial curing applications, and it continues to focus on new capabilities to meet clients’ needs.

“Every day we are working on new ways to polymerize or dry coat for different applications,” says Marine Faucher, global marketing manager. “Our technology covers so many different industrial applications, there’s no limit to what our technology can do in the field of curing. Sometimes the material that needs to be cured is a challenge, but we work with a large ecosystem across a range of partners – such as ink, chemical and substrate manufacturers – to find a solution.”

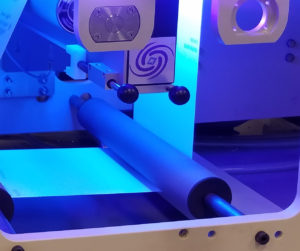

Hillsboro, Ore.-based Phoseon’s patented Semiconductor Light Matrix (SLM) technology involves LED arrays, optics, thermal and electrical management to ensure optimal performance. With reliability engineering at its core, the company is known for its thorough and proven product development cycle with advanced testing such as highly accelerated life testing. All the manufacturing is located in the United States.

“Our technology covers so many different industrial applications, there’s no limit to what our technology can do in the field of curing.”

Marine Faucher, global marketing manager, Phoseon Technology

The company is exploring machine vision systems on the assembly line and working towards automatic defect detection solutions. Phoseon is ISO-9001 certified with a global sales and support network.

The company’s industrial curing arm serves applications such as printing, electronics, OLED display manufacturing, wood and cable coatings and adhesive bonding with products that range from small air-cooled lamps to high-power water-cooled systems.

For the life sciences market, Phoseon’s solutions provide precisely controlled, long-lasting and stable light for biological inactivation, molecular detection and advanced imaging. It is dedicated to ensuring precision, yield, throughput and quality analysis. “We are the only UV LED experts with over 16 years’ experience in UV LED curing,” Faucher says. “Phoseon is the only company to be 100 percent dedicated to offering UV LED solutions. Most of the companies know about UV and use some UV curing systems, but they are not exclusively working on LEDs. The advantages of our technology are many. LED systems are long lasting and don’t have bulbs that need to be changed regularly like the UV solutions using mercury lamps. They also don’t require the use of extraction to remove heat and ozone.”

“Our systems require very little maintenance – you clean the window and make sure the filter is clean so it’s cooling properly,” she adds. ”The yield and operational cost is much better with UV LED than just a regular UV arc lamp solution. Our systems immediately reach the right level of functionality, you don’t have to wait for them to warm up thus saving immensely on energy costs, and they can run at higher speeds for greater press productivity. They are much more advantageous than the arc lamp UV systems.”

MEETING DEMAND

Phoseon aims to maintain its market leadership position by improving its operations in a number of ways. The company is increasing its use of automation during the testing process, and expanding its manufacturing space by more than 40 percent while redesigning the manufacturing floor. It also is setting up lean work cells to achieve single-piece flow by 2019. Faucher notes all of these enhancements are necessary for Phoseon to meet demand because the global UV LED market is expected to exceed $1.3 billion by 2025.

“Phoseon has been growing since we got started in 2002,” she says. “We have to increase our production site, and we are always adding new members to all the different teams.”

The company is operating almost equally in markets all over the world between the Americas, Europe, the Middle East and Asia, and it is responding to greater demand for fiber curing and electronic applications. “We offer a great solution for OLED displays,” Faucher says. “There is a lot of digital printing in Europe and the United States, too.”

The life sciences market is new for Phoseon, and it plans to expand in that area, as well. The company is using its LED capabilities and expertise for LED light engines and detectors across a wide range of applications with specific, narrow-band wave lengths. Its life sciences applications include disinfection, decontamination and chromatography.

”We are always trying to think ahead of our customers and anticipate the needs they can have,” Faucher says. ”With digital printing, for example, the request is to be able to print shorter runs to meet market demand. And the markets are tight: Manufacturers of labels using flexography, for example, have to be very reactive. UV LED drying systems are optimal because they don’t have ink curing issues, can help increase the speed of the press, can run -short runs, can change the substrate quickly and can print on a wider range of material.”

Conversely, she notes, ARC lamp systems generate a lot of heat and can’t print on thin substrates because the lamps will burn or melt them. Phoseon is proud of its technology and continues to take steps to remain the global market leader.

“We have been qualified for the La bel Industry Global Awards – we are an announced finalist. The winner will be announced in September,” Faucher says. ”We also just set up a wholly owned foreign entity in China to help us facilitate financial and service transactions in the Chinese market. It will make our sales and customer support in Asia easier, but more importantly, it’s showing a commitment to the Chinese market for Phoseon.

Tags: UV LED Industrial Curing | UV LED for Life Sciences | Manufacturing Today MagazineCategories: Coatings | Corporate | Electronics | Manufacturing | Printing, Digital | Printing, Flexo | Adhesives | Chemistry